Bruno Söhnle Glashütte

Exclusive precision from Glashütte

Progress and tradition are not a contradiction, and high quality and reasonable price don't have to exclude one another. With this approach, Bruno Söhnle in Glashütte has done something unique and since 2000 he has showcased high-quality exclusive quartz watches. In the portfolio, however, it is not only the Ronda quartz watches refined in the Glashütte Watch Workshop that set the pace, but excellent mechanical models as well.

In 2008, Bruno Söhnle introduced its first mechanical watch with manual winding and a specially developed 3/4 plate as part of the Mechanik Edition. A groundbreaking and successful step in the company's history. The mechanical watch segment now includes high-quality automatic calibers with and without complications. Firmly established in Glashütte, our timepieces from Bruno Söhnle meet the strict value-added requirements of the watchmaking metropolis, which were finally defined in the Glashütte Regulation of 2022.

Quartz

Manual Winding

Automatic Winding

Quartz – Precision since 1880

And this is how our unique Bruno Söhnle quartz movements work: A tiny gear train, connected to the hands, is set in motion by a battery. A small quartz crystal in the form of a tuning fork serves as the timekeeper, ensuring that the energy from the battery is regulated to the hands. The "piezoelectric effect," a physical discovery dating back to 1880, is responsible for this precise operation. Thanks to this effect, it is possible to precisely adjust the vibration frequency of a crystal under electrical voltage. In our wristwatches, the number of vibrations of the quartz crystal per second is 32,768, a universally defined and impressive value that highlights the precision of quartz watches."

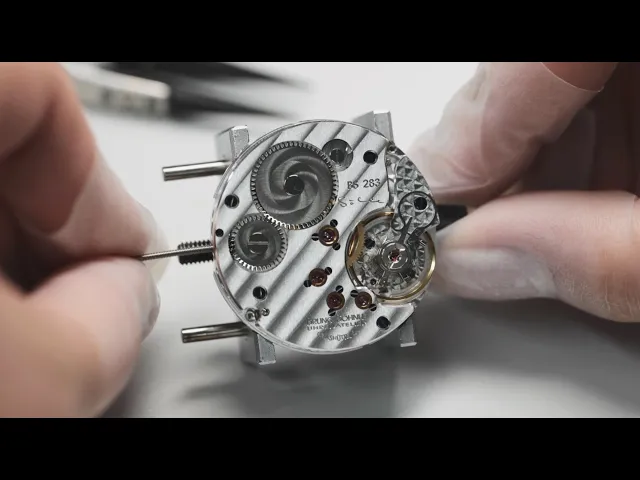

Manual Winding – Atelier Caliber BS 283

In 2008, Bruno Söhnle introduced the first mechanical watch with manual winding in its Mechanik Edition I. The Atelier Caliber BS 283, based on the Swiss ETA Unitas 6498, undergoes a complete transformation and decoration. The three-quarter plate, a proprietary development by Bruno Söhnle, is entirely manufactured in-house. This includes milling from a solid brass block, drilling, grinding, and engraving. The plate temporarily leaves our premises for galvanization. For final assembly, the jewels are set into 18-carat gold chatons and secured with thermally blued screws. Technical enhancements include the swan neck fine adjustment and the hacking seconds function. The pallet and crown wheels are enhanced with a sunburst finish.

Automatic Winding – Atelier Caliber BS 175

Two years after the release of the first timepiece with a manual winding caliber, the first mechanical watch with automatic winding was introduced in 2010. The automatic movements are equipped with a specially developed rotor responsible for winding the spring. It took over 2 years of development to harmonize the skeletonized design and functionality. The base plate, gear train, and automatic bridges are hand-finished with perlage, and the components are assembled with thermally blued screws. In addition to the 3-hand caliber (BS 175), there are mechanical movements with complications, such as a power reserve indicator (BS 509 G) or the well-known regulator (BS 509 R). This is achieved with the help of modules mounted on the movement by our watchmakers.